Lab Test: Frost Damage Tests on Stormdry

This was a laboratory test carried out by the research & development department at Safeguard Europe in 2010.

Test Aims

Due to the water resistant properties of Stormdry, it was surmised that a single coat application would be able to help limit frost damage on brick work. The research and development laboratory at Safeguard Europe was tasked with finding out how effective Stormdry is at protecting masonry and brick work from the damaging effects of the freeze/thaw cycle. They carried out the following test.

Test Method

The laboratory decided to test the effect of the freeze/thaw cycle on both Fletton brick and York sandstone. Four samples of the brick and four samples of the sandstone were tested in varied states, which were:

- Fletton Brick

- Treated with Stormdry (one coat)

- Treated with Stormdry (one coat)

- Treated with standard water repellent (two coats)

- Untreated (control example)

- York Sandstone

- Treated with Stormdry (one coat)

- Treated with Stormdry (one coat)

- Treated with standard water repellent (two coats)

- Untreated (control example)

In all cases, where a coating was applied, the samples were treated and then left for 2-3 days dry. All samples were then sealed around the edges with an acrylic waterproof sealer, to restrict water penetration to the face of the substrate. Each sample was then left for 1 month for the treatments to cure properly, before any further testing.

After all the sample items had been treated and cured, they were placed face down in 10mm depth of water. In order to simulate a freeze/thaw frost cycle, each sample was subjected to 16 hours at a temperature of -20°C followed by 8 hours at a temperature of 20°C. This process was repeated 18 times for each sample and the results were logged.

Results

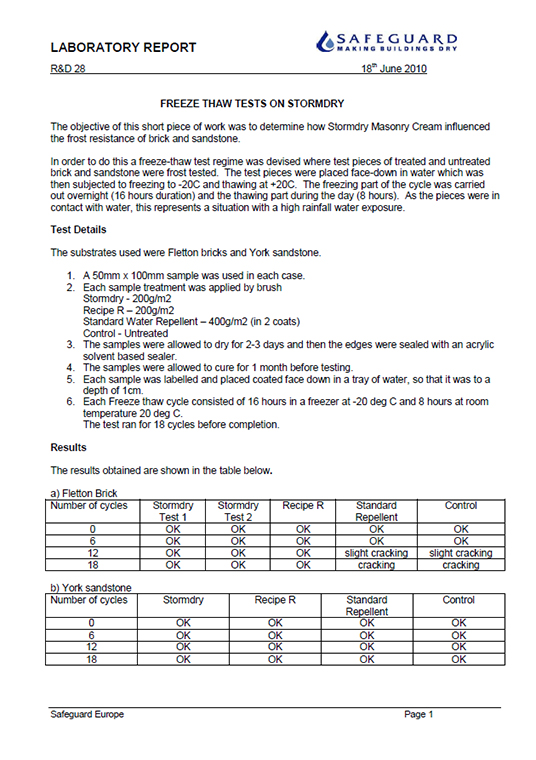

The Fletton brick samples that were not treated by Stormdry, including the samples treated with the standard water repellent, had begun to show slight cracking by the twelfth cycle and significant cracking by the completion of the eighteenth cycle. The damage to both the untreated and the standard water repellent bricks was nearly identical. The Stormdry treated bricks, however, consistently showed no signs of cracking and were unchanged from the beginning of the test.

The York sandstone samples, in comparison, showed no signs of wear or damage, regardless of whether they were treated with Stormdry or not. After the full 18 freeze/thaw cycles had been completed, no change could be observed in any of the sandstone samples.

Conclusion

The results show that Stormdry can protect standard Fletton brick work from damage by the freeze/thaw frost cycle. Frost damage is often directly related to the level of saturation within a brick or stone. Stormdry stops water from penetrating into the brick work and therefore stops damage occuring, due the expansion of ice within the brick’s capillaries. This makes Stormdry a very beneficial coating to apply to brick work.

Sandstone is a more robust material and can withstand frost damage much more than a Fletton brick. Although no freeze/thaw damage occurred, Stormdry is still a benefit to buildings made out of sandstone because it is a very porous material. Stormdry would protect a sandstone building from penetrating damp and, in the long term, would protect against frost damage as well.

For more information or to ask any questions, contact our technical department on 01403 220 130.